Case Study Overview

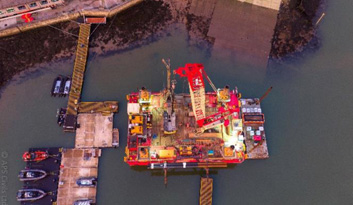

The existing mooring pontoon system at HMS Raleigh Naval Sea Training School had reached the end of its lifespan. The proposed £1.9-million-pound modernisation works being carried out by Falmouth Divers Ltd consists of replacing the existing pontoon network and the installation of two 610mm x 20m long rock-socked restraining guide piles to support the new 35m landing walkway.

At a glance

- Location: Torpoint, Plymouth 2020

- Plant used: 400t Jack-up Barge ‘Haven Seaseven’

- What we did: Red7Marine supported main contractor, Falmouth Divers Ltd, with the installation of two rock-socket restraint piles for a new landing pontoon platform

Why Red7Marine?

Red7Marine (R7M) operates the largest fleet of jack-up barges (JUB) in the UK. With a proven track record, we could offer Falmouth Divers Ltd the required resources with the added assurance that our elevated platform would provide a safe working platform to the client even in a challenging marine environment. This was a key factor as the project was programmed to be carried out over the winter months.

What makes the project standout?

The piling project was delivered from inception to installation on behalf of Falmouth Divers Ltd, with our in-house marine plant and labour. The works were carried out safely to the specification and within programme. The project’s programme dictated that the works could only be carried out over the winter break due to restraints within the Naval base. Key factors that led to the successes of the project are listed below:

- The R7M engineering department detailed the utilisation of the 400t jack-up barge at tender stage to Falmouth Divers Ltd, providing a full turn-key package. The modular jack-up barge provided a working platform which meant both piles could be installed in one location. This bore dividends in the timescale for completion, the monetary value of the project and the risk profile as only one setup was required.

- Rapid mobilisation – working in the harshest weather months of the year, it was integral that the project was completed safely and expediently within a two-week timeframe. All key items of marine plant and equipment were mobilised to site in just four days directly after the Christmas break.

- Both 610mm diameter piles were installed to level and within tolerance in four days to comply with license deadlines. R7M designed a bespoke piling gate to accommodate the pile and casing that could be easily transferred on-site to each piling location, therefore saving time and cost.

- The project was carefully planned in conjunction with Falmouth Divers Ltd and executed where R7M was able to deliver the full package of works from one barge in one primary location.

The Challenges and Solutions

- The site is located within a Naval base in close proximity to a Site of Significant Scientific Interest (SSSI). R7M worked closely with the client, Falmouth Divers Ltd, utilising a small site-team to find solutions to several key issues to ensure the necessary passes and consents were in place before the construction works commenced.

- The site information was restricted with historical data detailing an expected ground makeup comprising of hard sandstone. This unknown ground risk augmented the threat of on-site delay due to deferred drilling outputs. R7M mobilised with surplus drill tooling to overcome any unseen hard ground should it have arisen, mitigating the need for remobilisation.

- The 15t bespoke piling gate designed, detailed and manufactured in-house specifically for the project meant that both piles could be installed from one barge location quickly, safely and to tolerance.

- All works had to be planned within a constricted schedule. R7M utilised a small multi-skilled site team taken from our domestic labour pool specifically skilled in rock-socket installation. All required materials were loaded on to the barge before mobilisation making the team totally self-sufficient once on-site.

- The Project Manager and Engineer that supported the barge team on-site had been involved with the project from tender stage. This early involvement offered an in-depth knowledge and understanding of what was required having been involved with the project from the engineering solution stage.

Complete Package Delivery

Red7Marine provided equipment, crew and engineering support to the project to ensure our clients’ successful delivery of the marine jetty.

Solutions Provider

Red7Marine provided specialist jack-up barge and marine experience to the project. Bespoke deck layouts and designs were supplied throughout.

Skilled Team

Red7Marine’s operations and engineering teams are all highly skilled and experienced in the marine environment providing partners with an industry-leading service.

SEE RELATED CASE STUDIES

Westminster Pier Extension

The Westminster Pier Extension allows more frequent River Bus services between Woolwich and North Greenwich to Westminster. The extension is a key part of the River Action Plan to improve TfL’s piers and increase capacity for passengers before 2020. Red7Marine designed and built a custom pile gate for the project. The barge was reviewed to support a 180t crawler crane for piling operations and was then further reviewed with an additional RH28 drill rig on board.

Brighton Marina

Phase 2

In order to accommodate a new luxury apartment block in Brighton, part of the marina needed to be reclaimed using sheet piled cofferdams. This would enable the water to be kept out and foundations to be built for the stunning seafront properties. Red7Marine supported the installation of a sheet pile twin wall cofferdam.

Oldbury

Red7Marine installed replacement Active Effluent Discharge Lines at Oldbury power station as part of the on-going care and maintenance works. Red7Marine’s previous project experience on similar projects consisting of works on subsea pipeline and outfalls at Bradwell and Sizewell nuclear power stations, positioned the company as the ideal marine partner for client, Magnox.

Emirates Cable Car

The Emirates cable car was installed to provide a pedestrian link across the River Thames between the Royal Docks and the Greenwich peninsula. Red7Marine worked with Bachy Soletanche in a joint venture to install the foundations for the one-kilometre long cable car using marine rotary bored piling.

Middleton Sands Navigation Marker

This fast turn-around marine construction project involved the installation of a new tubular steel navigation marker pile at Middleton Sands, Barrow-in-Furness in 2017. The navigation marker was required to identify the sub surface obstructions and enable other vessels in the area to operate safely.

Liverpool 2 Deep Water Port Extension

Red7Marine was the marine partner of choice for BAM Nuttall when they constructed a piled combi-wall as part of the Liverpool 2 Dock Expansion that began in 2014. The construction of the container terminal was supported by four of Red7Marine’s jack up barges; the Haven Seariser 1, Haven Seariser 2 and the Haven Seariser 3 and the Haven Seajack as it carried out rock socket piling works.

Weston-Super-Mare

The Red7Marine team was chosen to provide specialist marine plant and personnel to aid the redevelopment of the Weston-super-Mare Grand Pier after it was destroyed in a fire in 2008. Red7Marine supplied the Haven Seajack 4 assisted in the pier construction works. Its previous experience in pier and marina construction works made it the ideal project partner for this development.

Bradwell Power Station Barrier Wall Removal

Red7Marine is a leading provider of equipment for marine demolition and is skilled in dismantling structures that are beyond the reach of ordinary demolition contractors. In 2012, Red7Marine removed approximately 800 tonnes of steel in the Blackwater Estuary from the Bradwell nuclear power station water intake structure.

Fingringhoe Firing Ranges

Red7Marine installed scour protection and provided remediation on damaged sections of the flood defences to preserve areas of the salt marsh at the Fingringhoe firing ranges in Essex. Scour protection and remediation techniques are used to control erosion in both estuarine and the offshore environments.