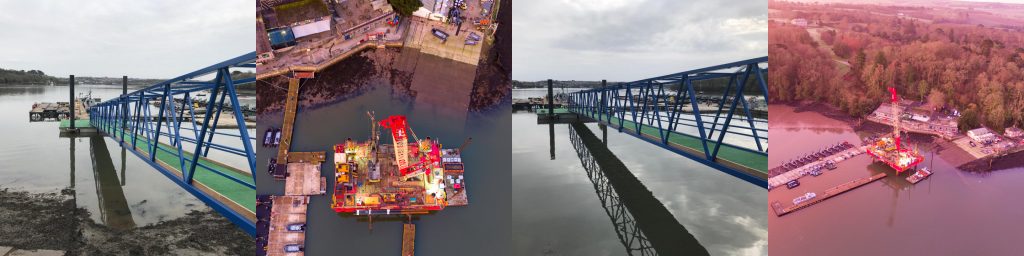

At the beginning of this year, our marine projects team successfully completed a self-delivery package at Jupiter Point in Plymouth installing two rock-socket restraint piles for a new landing pontoon platform supporting Falmouth Divers.

The existing mooring pontoon system at HMS Raleigh Naval Sea Training School had reached the end of its lifespan. The proposed £1-million-pound modernisation works consisted of replacing the pontoon network and the installation of two 610mm x 20m long rock socked restraining guide piles to support the new 35m landing walkway.

The piling project was delivered from inception to installation, with our in-house marine plant and labour. The works were carried out safely to the specification and within programme. The R7M engineering department detailed the utilisation of the 400t jack-up barge at tender stage providing a full turn-key package. The modular jack-up barge provided a working platform which meant both piles could be installed in one location. This bore dividends in the timescale for completion, the monetary value of the project and the risk profile as only one setup was required.

Kristen Branford, Managing Director comments: “The project at Jupiter Point is a great example of our ability to self-deliver the construction of rock-socket piles. Our team entered into early talks with the client and developed a solution that suited their needs. In this particular case, the client wanted to sub-contract the piling works to Red7Marine so we would be responsible for the installation of the rock socket piling.

This type of work showcases our ability to drill into rock from our jack-up barges, then install grouted steel piles into the sockets to a strict tolerance. Our in-house team of experts carried out the design of the temporary works, project managed the construction process and installed the piles on site. For this project, our 400t Haven Seaseven was used so we could accommodate a 100t drilling rig, alongside a 160t crawler crane, allowing the barge to work above the water and be less effected by the winter weather conditions on the water. However, we still had to work through Storm Ciara and Dennis, which involved the team carefully planning working operations around the high winds. We were glad we had made the choice to use our 400t Jack-up barge.

The project was on a MOD site which poses logistical challenges, but both the MOD and our client were very accommodating. It was a successful project which we are very proud of.”

Garry Duff, Engineer at Falmouth Divers comments: “Falmouth Divers Ltd contracted Red7Marine at the end of 2019 to undertake the installation of two rock-socketed piles at the Jupiter Point Royal Naval training facility near Torpoint.

The tender negotiation phase ran smoothly, and a contract was awarded in December 2019 with a plan to start work on-site in Plymouth in January 2020.

Red7Marine mobilised its SeaSeven jack-up vessel from Liverpool and transited it to Plymouth in early January through a gap in the seasonally bad weather. The mobilisation was conducted efficiently within a week as planned.

The drilling and installation of the two piles on-site at Jupiter Point were conducted successfully despite two major storm events during the period. There was a strong focus on site health and safety culture throughout the project and quality control was maintained with a strong in-house surveying capability.

FDL, our client, and the end user, was extremely pleased with work and the way it was conducted. FDL agreed the final account with Red7Marine within 14 days of the completion of works.

We would highly recommend Red7Marine for any challenging marine civil engineering projects.”

“OUR MARINE PARTNER OF CHOICE FOR ROCK-SOCKET PILING.”